YA-VA Pallet Conveyor System (components)

Essential Details

|

Condition |

New |

|

Warranty |

1 Year |

|

Applicable Industries |

Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Food Shop, Printing Shops, Food & Beverage Shops |

|

Weight (KG) |

0.92 |

|

Showroom Location |

Viet Nam, Brazil, Indonesia, Mexico, Russia, Thailand, South Korea |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

|

Place of Origin |

Jiangsu, China |

|

Brand Name |

YA-VA |

|

Product name |

Idler unit for roller chain |

|

Effective track length |

310 mm |

|

Sidewall position |

left / right |

|

Keyword |

pallet conveyor system |

|

Body material |

ADC12 |

|

Drive shaft |

Zinc coated carbon steel |

|

Drive sprocket |

Carbon steel |

|

Wear strip |

Antistatic PA66 |

|

Color |

Black |

Product Description

| Item | Sidewall position | Effective track length(mm) | Unit weight(kg) |

| MK2TL-1BS | On the left | 3100 | 0.92 |

| MK2RL-1BS | On the right | 0.92 |

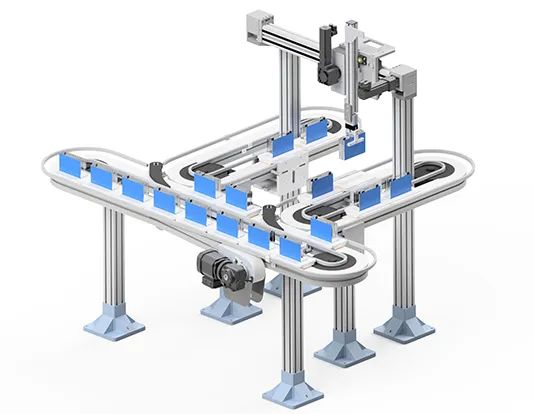

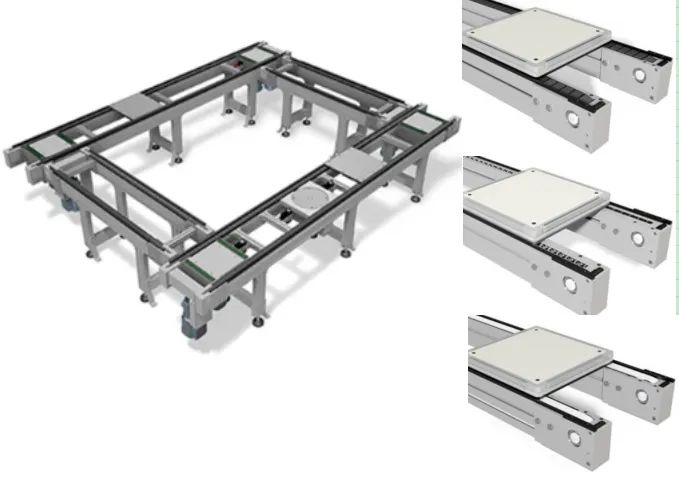

Pallet Conveyors

Pallet conveyors to track and carry product carriers

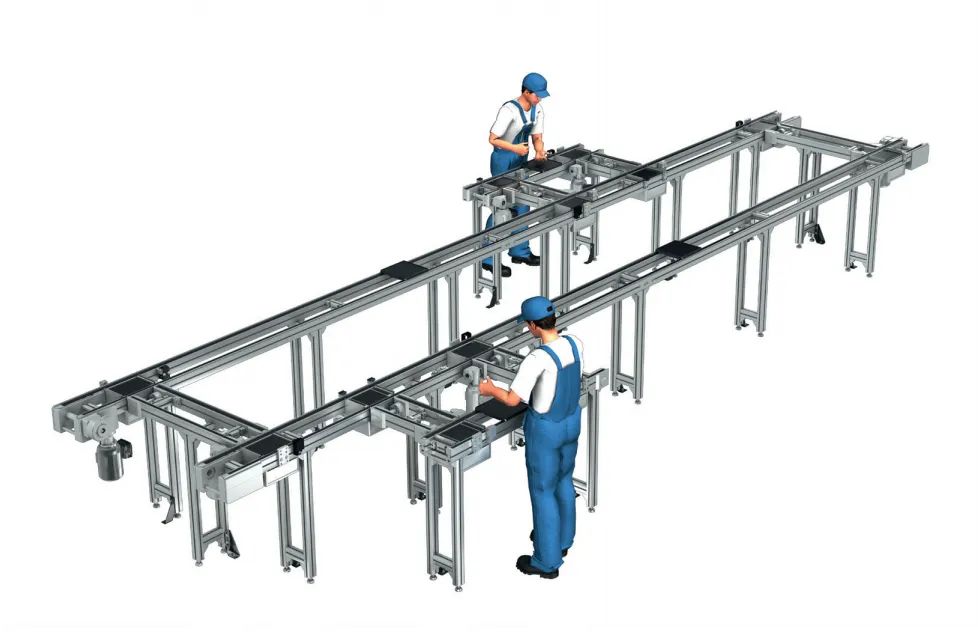

Pallet conveyors handle individual products on product carriers such as pallets. Each pallet can be adapted to varying environments, from medical device assembly to engine component production. With a pallet system, you can achieve a controlled flow of individual products throughout the complete manufacturing process. Unique identified pallets allows for creating specific routing paths (or recipes), depending on the product.

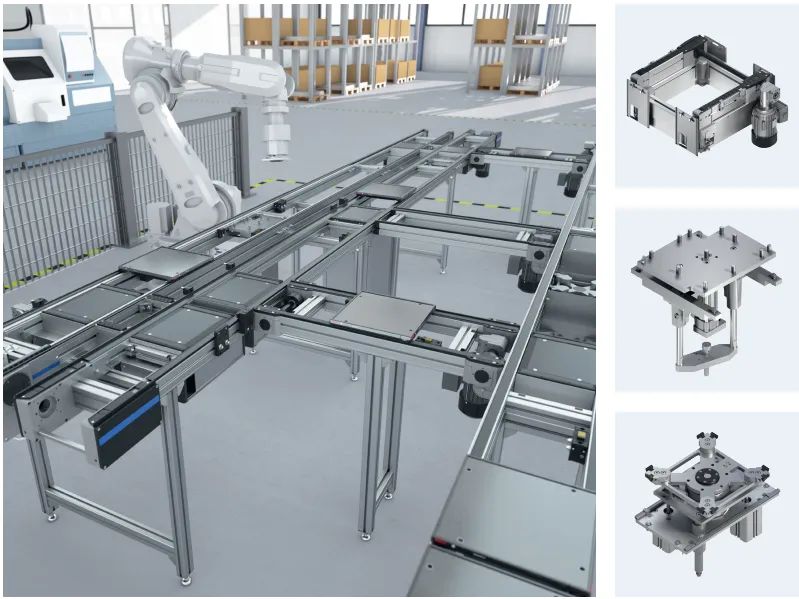

Based on the standard chain conveyor components, single-track pallet systems are a cost-efficient solution to handle smaller and lightweight products. For products with a considerable size or weight, a twin-track pallet system is the right choice.

Both pallet conveyor solutions use configurable standard modules that make it easy and fast to create advanced but straightforward layouts, allowing routing, balancing, buffering and positioning of pallets. RFID identification in the pallets enables one-piece track-and-trace and helps to achieve logistic control for the production line.

1. It is a diverse modular system that meets the requirements of a wide range of different products.

2. Diverse, sturdy, adaptable;

2-1) three types of conveyor media (polyamide belts, toothed belts and accumulation roller chains) which can be combined together to meet the needs of the assembly process

2-2)Workpiece pallets dimensions (from 160 x 160 mm up to 640 x 640 mm) specifically designed for the product sizes

2-3)A high maximum load of up to 220 kg per workpiece pallet

3. Apart from the different types of conveyor media, we also provides an abundance of specific components for curves, transverse conveyors, positioning units and drive units. The time and effort spent on planning and designing can be reduced to a minimum using predefined macro modules.

4.Applied to many industry, such as new-energy industry, Automobile, battery industry and so on

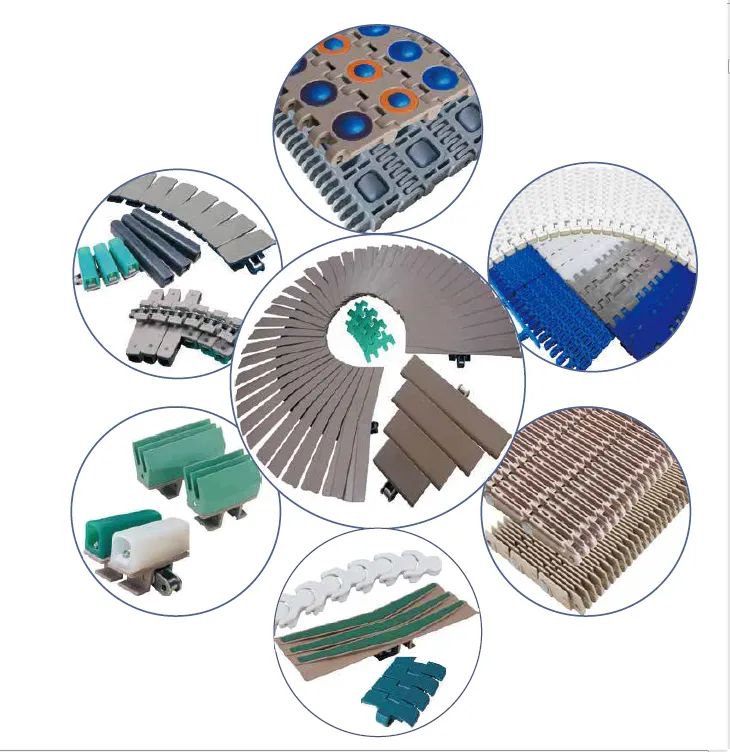

Conveyor Accessories

Conveyor Components: Modular belt and Chain accessories, side guide rails, guie brackets and clamps, plasstic hinge, leveling feet, cross joint clamps, wear strip, conveyor roller, side roller guide, bearings and so on.

Conveyor Components: Aluminum Chain Conveyor System Parts ( support beam, drive end units, beam bracket, conveyor beam, vertical bend, wheel bend, horizontal plain bend, idler end units, aluminum feet and so on)

BELTS & CHAINS: Made for all kind of products

YA-VA offers a wide range of conveyor chains. Our belts and chains are suitable to transport products and goods of any industry and customizable to widely varying requirements.

The belts and chains consist of plastic hinged links connected by plastic rods. They are woven together by links in a wide dimension range. The assembled chain or belt forms a wide, flat, and tight conveyor surface. Various standard widths and surfaces for different applications are available.

Our product offer ranges from plastic chains, magnetic chains, steel top chains, advanced safety chains, flocked chains, cleated chains, friction top chains, roller chains, modular belts, and more. Feel free to contact us for a consultation to find a suitable chain or belt for your production needs.

Conveyor Components: Pallets Conveyor System Parts ( tooth belt, hig-strength transmission flat belt, roller chain, dual drive unit, idler unit, wear strip, agnle bracket, support beams, support leg, adjustable feet and so on.)

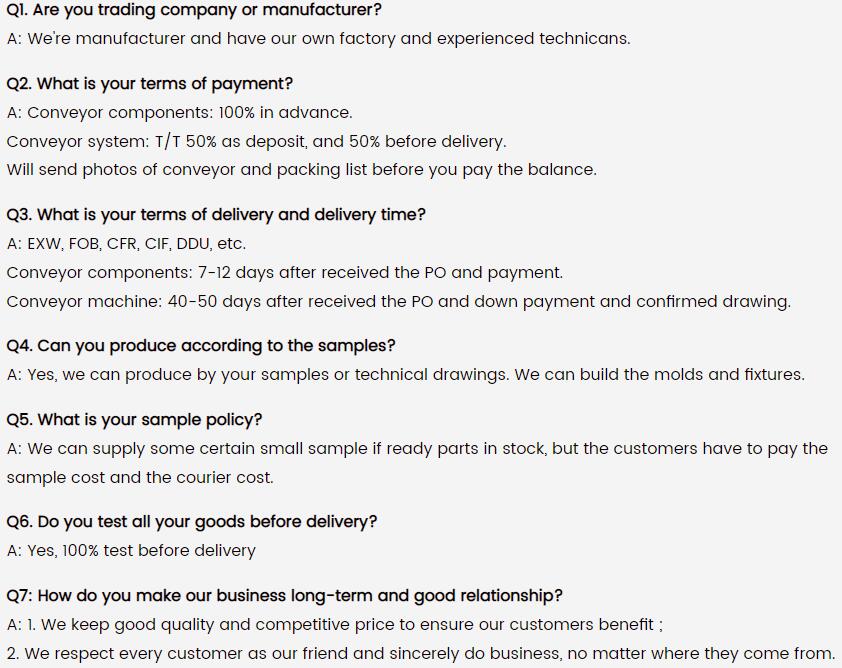

FAQ

About YA-VA

YA-VA is a leading high-tech company providing intelligent conveyor solutions.

And it consists of Conveyor Components Business Unit;Conveyor Systems Business Unit; Overseas Business Unit (Shanghai Daoqin International Trading Co., Ltd.) and YA-VA Foshan Factory.

We are an independent company that has developed, produces and also maintains the conveyor system to ensure that our customers receive the most cost effective solutions available today. We design and manufacture spiral conveyors, flex conveyors, pallet conveyors and integrated conveyor systems and conveyor accessories etc.

We have strong design and production teams with 30,000 m² facility, We have passed IS09001 management system certification, and EU & CE product safety certification and where needed our products are food grade approved. YA-VA has an R & D, injection and molding shop, components assembly shop, conveyor systems assembly shop, QA inspection center and warehousing. We have professional experience from the components to customized conveyor systems.

YA-VA products are widely used in food industry, daily use industry, beverage in industry, pharmaceutical industry, new energy resources, express logistics, tire, corrugated cardboard, automotive and heavy-duty industries etc. We have been focusing on conveyor industry more than 25 years under YA-VA brand. Currently there are more than 7000 clients worldwide.