Plastic modular belt drive conveyor sprocket–SS881

Applicable Industries:

| Food | electronics | pharmaceutical | Logistics |

|

|

|

|

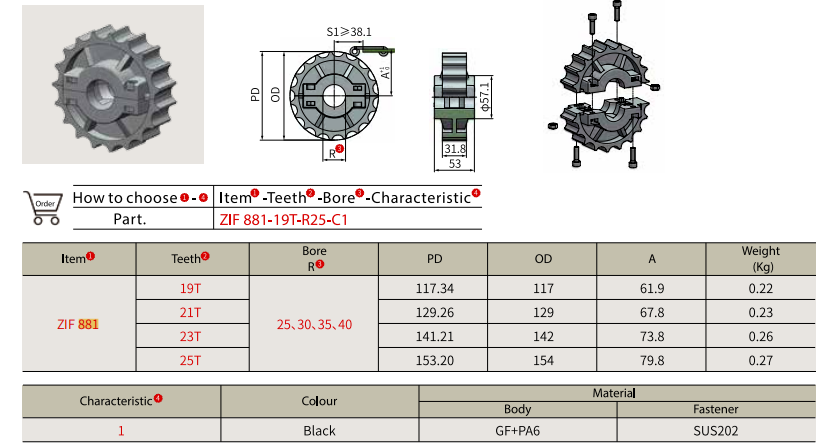

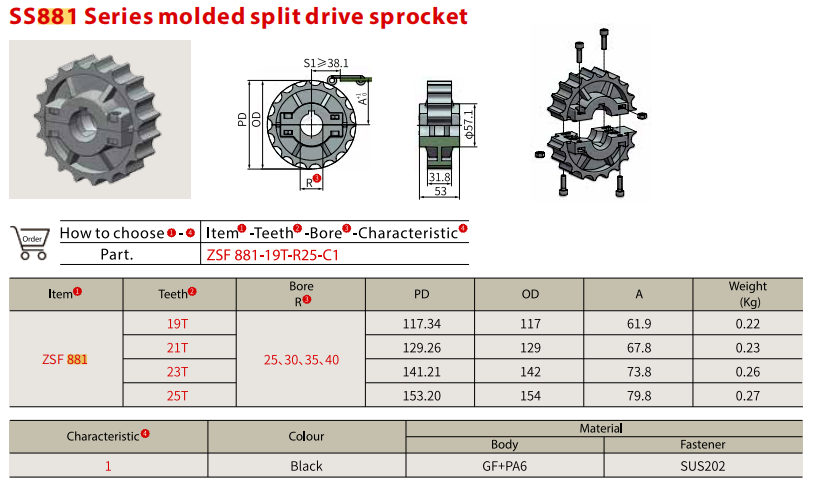

Technical Parameters:

(Drive Sprocket)

| Item | Teeth | Bore | Pd | OD | A | Weight |

| ZSF881 | 19T | 25、30、35、40 | 117.34 | 117 | 61.9 | 0.22 |

| 21T | 129.26 | 129 | 67.8 | 0.23 | ||

| 23T | 141.21 | 142 | 73.8 | 0.26 | ||

| 25T | 153.20 | 154 | 79.8 | 0.27 |

(Idler Sprocket)

| Item | Teeth | Bore | Pd | OD | A | Weight |

| ZIF881 | 19T | 25、30、35、40 | 117.34 | 117 | 61.9 | 0.22 |

| 21T | 129.26 | 129 | 67.8 | 0.23 | ||

| 23T | 141.21 | 142 | 73.8 | 0.26 | ||

| 25T | 153.20 | 154 | 79.8 | 0.27 |

| characteristic | colour | Material

|

|||

| 1 | Black | GF+PA6 | SUS202 | ||

Feature:

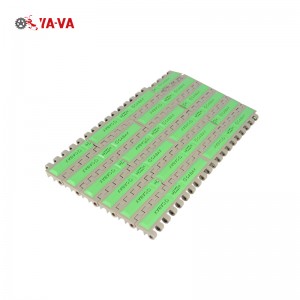

1、Based on different technological processes, slat chain can be divided into straight running type and flexible running type.

2、 More importantly, the plastic chain conveyor installation is very simple, easy to operate.

3、 Plastic chain conveyor adopts standard slat chain as the carrying surface, motor speed reducer as the power, running on the special rail. The conveying surface is flat and smooth and the friction very lower.

4、Single-row conveying can be used for beverage labeling, filling, cleaning and so on. Multi-row conveying can meet

Detail

Write your message here and send it to us

-300x300.jpg)