The working principle of a conveyor belt is based on the continuous movement of a flexible belt or a series of rollers to transport materials or objects from one place to another. This simple yet effective mechanism is widely used in various industries for efficient material handling. Here’s a detailed explanation of how a conveyor belt works:

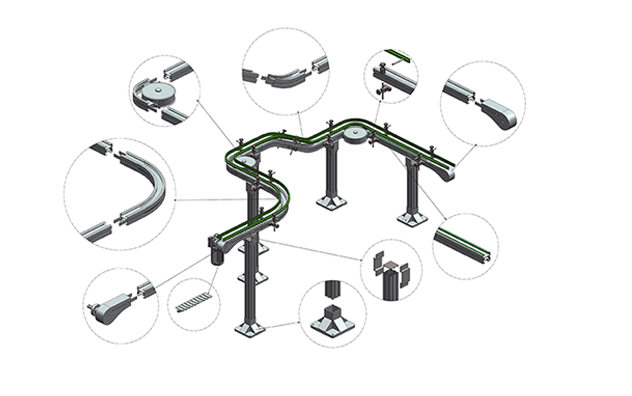

Basic Components

-

Belt: The belt is the primary component that carries the load. It is usually made of rubber, fabric, or other durable materials.

-

Pulleys (Drum Wheels): Pulleys are located at both ends of the conveyor system. The drive pulley is powered by a motor, while the tail pulley redirects the belt.

-

Idlers (Rollers): These are small rollers placed along the length of the conveyor to support the belt and ensure smooth movement.

-

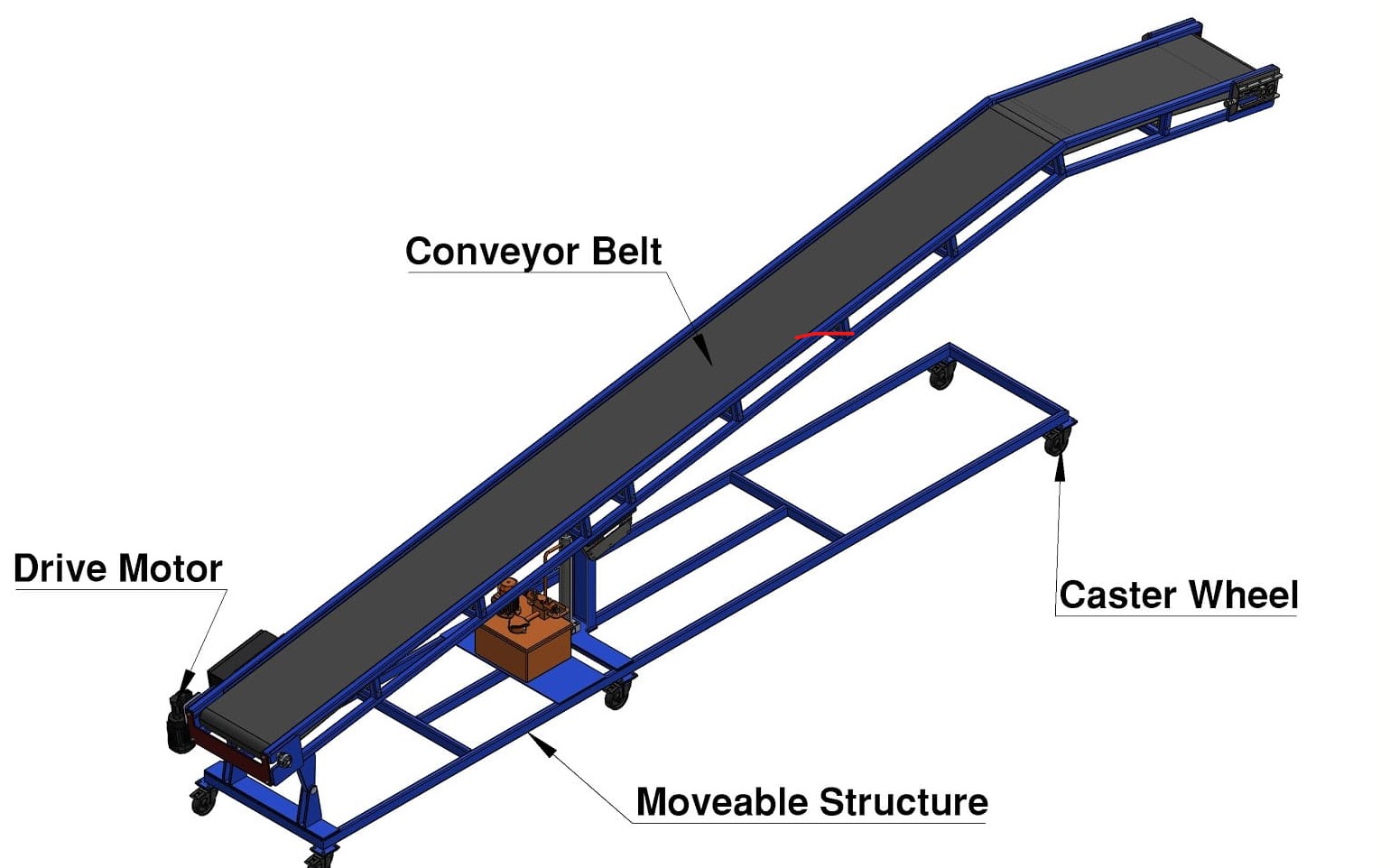

Motor: The motor provides the power to drive the pulley, which in turn moves the belt.

-

Frame: The frame supports the entire conveyor system and ensures stability.

-

Tensioning Device: This adjusts the tension of the belt to prevent slippage and ensure proper operation.

Working Principle

-

Power Transmission:

- The motor generates mechanical power, which is transmitted to the drive pulley through a gearbox or a direct drive mechanism.

- The drive pulley rotates, and its motion is transferred to the belt through friction.

-

Belt Movement:

- As the drive pulley rotates, it causes the belt to move continuously in a loop.

- The belt runs over the idlers, which help guide and support the belt, ensuring it remains taut and stable.

-

Material Loading and Transport:

- Materials or objects are placed on the belt at the loading point.

- The belt carries the load along its length to the discharge point, where the materials are unloaded.

-

Return Path:

- After the load is discharged, the empty belt returns to the loading point via the tail pulley, completing the loop.

Key Factors Affecting Conveyor Operation

- Belt Speed: The speed at which the belt moves is determined by the motor’s RPM (revolutions per minute) and the pulley diameter. Faster speeds can increase throughput but may also require more power.

- Load Capacity: The amount of material the conveyor can handle depends on the belt’s strength, width, and the motor’s power. Overloading can cause the belt to slip or the motor to overheat.

- Belt Tension: Proper tension ensures the belt remains taut and prevents slippage. Tensioning devices, such as take-up pulleys, are used to adjust the belt tension.

- Friction: The friction between the belt and the pulleys is crucial for the belt’s movement. Insufficient friction can cause slippage, while excessive friction can lead to wear and tear.

Types of Conveyors

- Flat Belt Conveyor: Used for general-purpose material handling. The belt is flat and moves horizontally or at a slight incline.

- Incline Conveyor: Designed to transport materials up or down an incline. These conveyors often have cleats or side walls to prevent material from slipping.

- Roller Conveyor: Uses rollers instead of a belt to move items. Suitable for handling heavy or bulky objects.

- Screw Conveyor: Uses a rotating helical screw to move materials through a tube. Ideal for conveying powders, grains, and other bulk materials.

- Pneumatic Conveyor: Uses air pressure to move materials through a pipeline. Suitable for fine powders and granules.

Advantages of Conveyor Systems

- Efficiency: Conveyors can handle large volumes of material with minimal manual intervention, increasing productivity.

- Automation: They can be integrated into automated systems, reducing labor costs and improving accuracy.

- Versatility: Available in various types and configurations to suit different applications and environments.

- Reliability: With proper maintenance, conveyors can operate continuously with minimal downtime.

Maintenance Tips

- Regular Inspection: Check the belt for wear, tears, and misalignment. Inspect pulleys and idlers for damage.

- Lubrication: Keep the moving parts well-lubricated to reduce friction and wear.

- Tension Adjustment: Regularly check and adjust the belt tension to ensure optimal performance.

- Cleanliness: Keep the conveyor and surrounding area clean to prevent material buildup and reduce the risk of accidents.

By understanding the working principle of a conveyor belt and following proper maintenance practices, you can ensure efficient and safe material handling in your operations.

Post time: Feb-10-2025