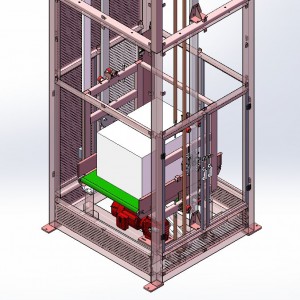

Continuous Vertical Conveyor Lift Vertical Conveyors Lifters/Continuous Vertical Transfer Conveyor System For Cartons, Bags, Pallet

Product Description

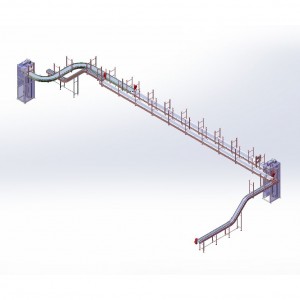

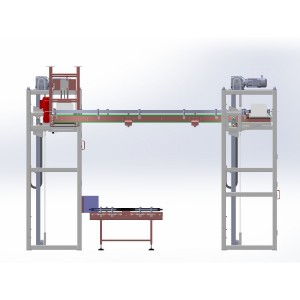

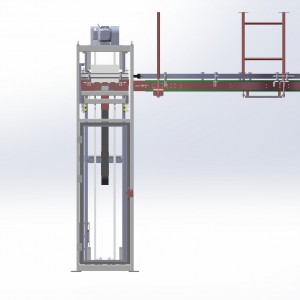

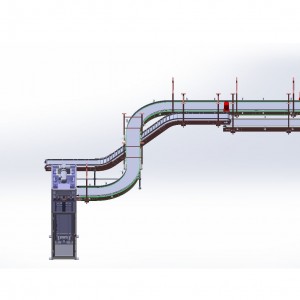

Vertical lift conveyor are used to elevate or lower containers, boxes, trays, packages, sacks, bags, luggage, pallets, barrels, kegs, and other articles with a solid surface between two levels, quickly and consistently at high capacity; on automatically loading platforms, in "S" or "C" configuration, on a minimum footprint.

There are two types: C and Z

We can customer-built the vertical transfer system specially to meet your requirements. VTS Series vertical transfer system for cartons ,bags, pallet or other products vertical conveying. Link upper and lower floors to reach saving labor and space, improve efficiency purposes. The elevation and loading capacity can be customer built. It can be installed both indoor and outdoor according to worksite environment.

Standard

1, Back switch at rear of conveyor lining, to stop conveyor if tray or bus box has not been removed.

2, Lintel switch, to stop conveyor if any object protrudes beyond lining of conveyor, on ascending conveyors.

3, Sill switch, to stop conveyor if any object protrudes beyond the lining of conveyor, on descending conveyors.

4, Automatic override switch at top of shaft.

5, Bottom switch, to stop conveyor if tray or bus box has not exited from shaft, on descending conveyors.

6, Each floor has panel with clearing button, emergency stop button, and indicator light showing conveyor is in operation.

Advantages

* Vertical lifts help reduce costs, increase safety

* Used for conveying upward and downward

* Economical vertical transport for new or retrofit installations

* Move loads of all types (pallets, cartons and more), sizes and weights up to 400KG

* Modular frame, smooth transportation, safe and reliable;

* High efficiency:no wasted time from reverting pallets,high efficiency.

* Continuous working in two ways.

* Fully automatic with input and out put conveyors

* Compact in size,either indoors or outdoors